Brief description of equipment

-

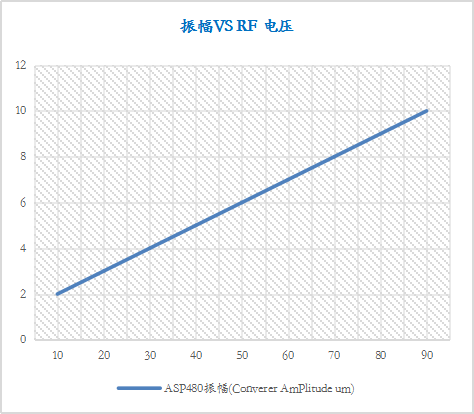

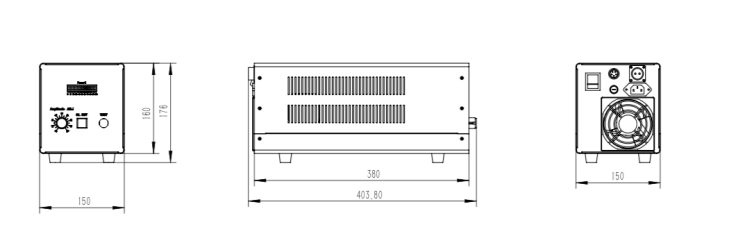

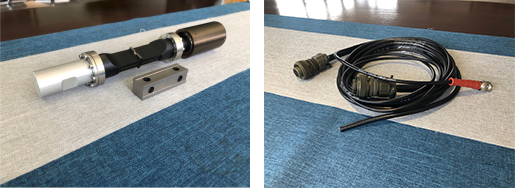

ASP series new ultrasonic power generator adopts advanced voltage parallel circuit design with phase locked loop, It has excellent performance in equipment performance, welding consistency and welding speed In high-quality applications, its cost performance advantage is more prominent, with the highest power volume ratio (i.e It provides the maximum power output in the smallest space. It can be automatically used by users. On the model. Depending on frequency power, size and installation (water At present, there are mainly two kinds of 800W at 40KHz of ASP 480, Widely used in consumer battery welding, zipper welding, car door panel welding, tire cutting and other lines And has been highly praised by customers.

What should I do if the generator or transducer fails?

How to deal with the problems that often occur in the transducer of ultrasonic cleaners?

What should I do if the generator or transducer fails?

How to deal with the problems that often occur in the transducer of ultrasonic cleaners?